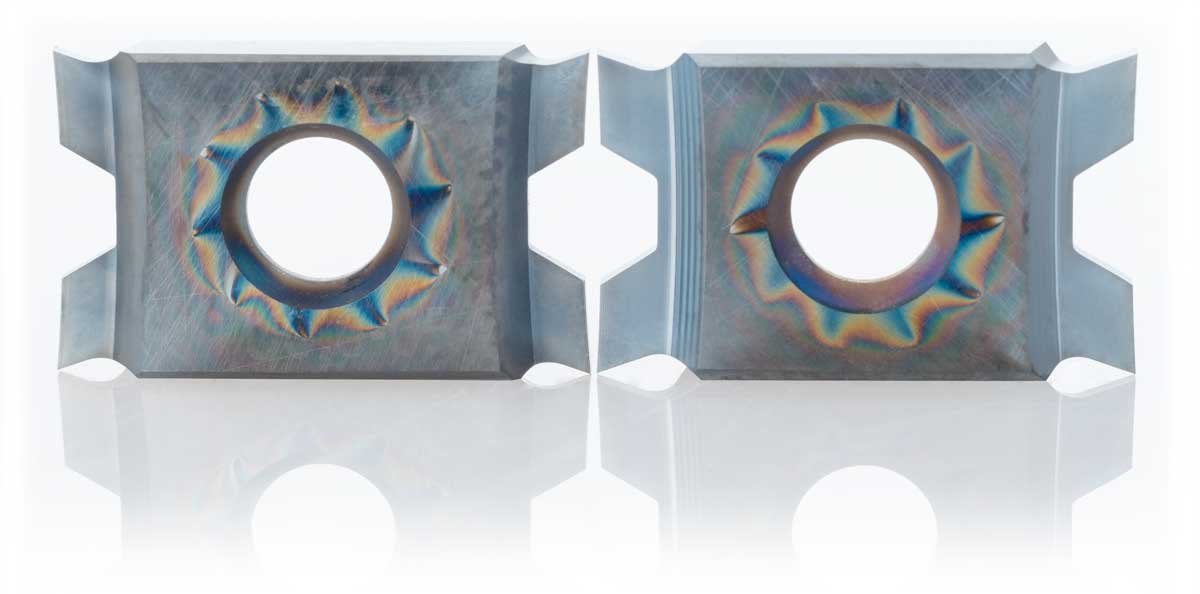

1. Tool wear

The gradual failure of the grooving insert/cutting edge changes groove width. But it can be postponed. |

WhizCut aid:

The combination of a strong cutting edge, and excellent chip flow reduces the stress of the cutting tip and prolongs tool life. Together with WhizHip tool holders the cutting edge is perfectly cooled and the chip-flow increases even more. |

2. Consistency & tolerance

Making grooves with tight tolerances and changing cutting edge or insert can be a time consuming job in tight tolerance production.

|

WhizCut aid:

All inserts from WhizCut are designed to reduce indexability tolerances. The WhizGroove insert indexes +/- 0,01 mm in center height and width. This minimizes risk of part change after insert indexing. |

3. Long cycle times

A two plunge/groove turn is needed to secure groove width. The part bends and give unroundness if taken the whole width. |

WhizCut aid:

The seating of the WhizGroove insert, in the tool holder, gives extra stability giving the possibility to push the tooling hard. WhizGroove inserts can also be made as specials - making a radius or chamfer at the outer corner of the grooves. |

4. Chips

Chip control is an issue with problems as chip wrap. |

WhizCut aid:

The chip control is set at an angle, which steers the chips away from the part. If the chips do not break, they are curled tightly making them very manageable. With WhizHip the chip control is improved even more - with a minimal risk of chip wrap. |