|

Press release WhizCut External Tooling for

small lathes 9711

WhizCut of Sweden AB has developed

a range of turning tools for CNC Swiss type automatics and other

small lathes. The main feature of the tooling range is that it

has two types of clamping. One with centerlock screw and one with

a special pin type clamping, which allow the inserts to be

changed from either the chuck or collet side, or alternatively,

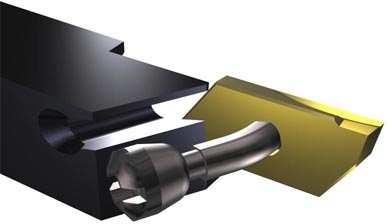

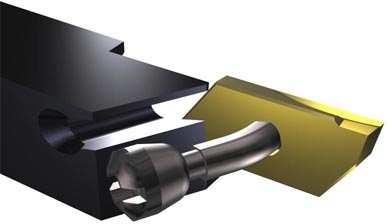

from the side away from chuck or collet. The later design of

toolholder has a slot into which a bent pin with nut and insert

can be fitted. The insert can easily be indexed or changed from

the opposite side to the cutting edge. The bent pin, tapered nut,

slot and countersink in the holder gives the tool several special

characteristics:

- The pin will not twist

when tightening the nut

- The tool is backed off

30° from its cutting point.

- The insert is securely

pulled and locked into its position in the pocket.

- The insert can be

quickly, easily and accurately indexed or changed

from the opposite side

The insert is claimed to be

indexed in 15 seconds and changed in 30 seconds in the pin type

toolholder even if the toolholder is mounted in a gang tool setup

with only 15 mm between the tools. The pin type tool is therefore

ideal in machines with gang tools where there is only access on

the side away from the inserts cutting edge.

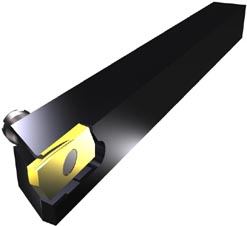

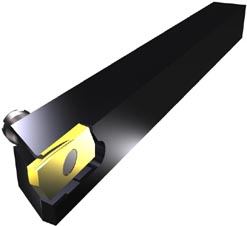

The toolholder with centerlock screw uses the same vertically

mounted insert as the pin type toolholder. This toolholder is for

normal lathes where the cutting edge side has plenty of room.

The WhizCut range consists of toolholders and inserts for

turning, copy-turning, groove-turning, rough-turning or

chamfering, grooving, facing, threading and parting off with

parallel, 6° or 15° edge. All the inserts have fully ground

cutting edges and are available with various cutting rakes from

0-20° in both uncoated and PVD coated grades.

Download word - document (258kb zipped)

|