Inserts for Turning and Copy Turning

Selecting the Right Tool for Turning

1. Axial Relief vs Component Possibilities

- 3° Gives the strongest tool and smoother finish

- 12° Gives a strong tool and good finish

- 33° Medium strong tool, wiper good for smooth finish

- 48-53°: less strong tool, wiper needed for smooth finish

|

2. Chip Control

- Style H = Long chips and/or high feed rate

- Style J = Long chips and/or highest feed rate

- Style D, N & V = Short chips and/or low to moderate feed rate

- Style M = Short chips and/or low to moderate feed rate

- Style HP, JP, VP = Long chips and/or low to moderate feed rate

|

|

Sharp Corner

|

Wiper

|

Full Radius

|

Radius+Wiper

|

|

3. Cutting Rake vs Material

- 0-2° for short-chipping materials

- 3-8° for harder long-chipping materials

- 8-16° for long-chipping materials

- 16-20° for sticky long-chipping materials

- HP, JP, VP style inserts for sticky and exotic materials

|

4. Corner Alternatives

Sharp corner = Minimum cutting force, good when component is weak.

Wiper = For higher feed-rates resulting in better surface finish.

Radius = Stronger tool also used upon request of component.

Wiper and radius = For higher feed-rate with better surface.

|

Style H | Inserts

for Turning

| |

|

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

L |

V° |

R |

C |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| J15ER H6-0 |

15 |

3 |

0 |

0 |

6 |

r |

k |

r |

r |

- |

- |

A3 |

| J15ER H6-05 |

15 |

3 |

0,05 |

0 |

6 |

r |

k |

r |

r |

- |

- |

A4 |

| J15ER H6-2 |

15 |

3 |

0,2 |

0 |

6 |

r |

k |

r |

r |

r |

r |

A4 |

| J15ER H16-0 |

15 |

3 |

0 |

0 |

16 |

r |

k |

r |

r |

- |

- |

A3 |

| J15ER H16-1 |

15 |

3 |

0,1 |

0 |

16 |

r |

k |

r |

r |

r |

r |

A4 |

| J15ER H16-2 |

15 |

3 |

0,2 |

0 |

16 |

r |

k |

r |

r |

- |

- |

A4 |

|

|

Style J | Inserts for Turning

| |

|

V° |

|

|

Cutting

rake° |

Stock |

Price

group |

| Inserts |

L |

R |

C |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| J11ER/L J8-0 |

11 |

12 |

0 |

0 |

8 |

a |

k |

a |

a |

- |

- |

A3 |

| J11ER/L J8-2 |

11 |

12 |

0,2 |

0 |

8 |

a |

k |

a |

a |

r |

r |

A4 |

| J11ER/L J20-0 |

11 |

12 |

0 |

0 |

20 |

a |

k |

a |

a |

- |

- |

A3 |

| J11ER/L J20-05 |

11 |

12 |

0,05 |

0 |

20 |

a |

k |

a |

a |

- |

- |

A4 |

| J11ER/L J20-2 |

11 |

12 |

0,2 |

0 |

20 |

a |

k |

a |

a |

- |

- |

A4 |

| J15ER/L J8-0 |

15 |

12 |

0 |

0 |

8 |

a |

k |

b |

b |

r |

r |

A3 |

| J15ER/L J8-1 |

15 |

12 |

0,1 |

0 |

8 |

a |

k |

b |

b |

r |

r |

A4 |

| J15ER/L J8-2 |

15 |

12 |

0,2 |

0 |

8 |

a |

k |

b |

b |

r |

r |

A4 |

| J15ER/L J20-0 |

15 |

12 |

0 |

0 |

20 |

a |

k |

b |

b |

- |

- |

A3 |

| J15ER/L J20-1 |

15 |

12 |

0,1 |

0 |

20 |

a |

k |

b |

b |

- |

- |

A4 |

| J15ER/L J20-2 |

15 |

12 |

0,2 |

0 |

20 |

a |

k |

b |

b |

- |

- |

A4 |

| J20ER J8-2 |

20 |

12 |

0,2 |

0 |

8 |

r |

k |

r |

r |

r |

r |

A21 |

| J20ER J8-4 |

20 |

12 |

0,4 |

0 |

8 |

r |

k |

r |

r |

r |

r |

A21 |

| J20ER J20-2 |

20 |

12 |

0,2 |

0 |

20 |

r |

k |

r |

r |

r |

r |

A23 |

| J20ER J20-4 |

20 |

12 |

0,4 |

0 |

20 |

r |

k |

r |

r |

r |

r |

A23 |

|

|

Style D | Inserts for Finish Turning

| |

|

V° |

|

|

Cutting

rake° |

Stock |

Price

group |

| Inserts |

L |

R |

C |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| J11ER/L D2-0 |

11 |

33 |

0,02 |

0 |

2 |

a |

k |

a |

a |

- |

- |

A5 |

| J11ER/L D2-0-1 |

11 |

33 |

0 |

0,12 |

2 |

a |

k |

a |

a |

- |

- |

A5 |

| J11ER/L D12-0 |

11 |

33 |

0,02 |

0 |

12 |

a |

k |

a |

a |

- |

- |

A5 |

| J11ER/L D12-05 |

11 |

33 |

0,05 |

0 |

12 |

a |

k |

a |

a |

- |

- |

A5 |

| J11ER/L D12-0-1 |

11 |

33 |

0 |

0,12 |

12 |

a |

k |

a |

a |

- |

- |

A5 |

| J15ER/L D2-0 |

15 |

33 |

0,02 |

0 |

2 |

b |

k |

b |

b |

- |

- |

A5 |

| J15ER/L D2-0-2 |

15 |

33 |

0 |

0,2 |

2 |

b |

k |

b |

b |

- |

- |

A5 |

| J15ER/L D12-0 |

15 |

33 |

0,02 |

0 |

12 |

b |

k |

b |

b |

- |

- |

A5 |

| J15ER D16-1 |

15 |

33 |

0,1 |

0 |

16 |

r |

k |

r |

r |

- |

- |

A5 |

| J15ER/L D12-0-2 |

15 |

33 |

0 |

0,2 |

12 |

b |

k |

b |

b |

- |

- |

A5 |

| J15ER/L D12-1-3 |

15 |

33 |

0,15 |

0,3 |

12 |

b |

k |

b |

b |

r |

r |

A6 |

| J20ER D2-2-5 |

20 |

33 |

0,2 |

0,5 |

2 |

r |

k |

r |

r |

r |

r |

A23 |

| J20ER D12-2-5 |

20 |

33 |

0,2 |

0,5 |

12 |

r |

k |

r |

r |

r |

r |

A24 |

|

|

Style N | Inserts

for Finish Turning

| |

|

V° |

|

|

Cutting

rake° |

Stock |

Price

group |

| Inserts |

L |

R |

C |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| J15ER/L N2-0-2 |

15 |

48 |

0 |

0,2 |

2 |

b |

k |

b |

b |

- |

- |

A6 |

| J15ER N2-1-3 |

15 |

48 |

0,1 |

0,3 |

2 |

r |

k |

r |

r |

- |

- |

A7 |

| J15ER/L N12-0-2 |

15 |

48 |

0 |

0,2 |

12 |

b |

k |

b |

b |

- |

- |

A6 |

| J15ER N12-1-3 |

15 |

48 |

0,1 |

0,3 |

12 |

r |

k |

r |

r |

r |

r |

A7 |

| J20ER N2-2-5 |

20 |

48 |

0,2 |

0,5 |

2 |

r |

k |

r |

r |

r |

r |

A24 |

| J20ER N12-2-5 |

20 |

48 |

0,2 |

0,5 |

12 |

r |

k |

r |

r |

- |

- |

A25 |

|

|

Style V | Inserts

for Finish and Copy Turning

| |

|

V° |

|

|

Cutting

rake° |

Stock |

Price

group |

| Inserts |

L |

R |

C |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| J11ER/L V2-1 |

11 |

53 |

0,1 |

0 |

2 |

a |

k |

b |

b |

- |

- |

A6 |

| J11ER/L V12-05 |

11 |

53 |

0,05 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A7 |

| J11ER/L V12-2 |

11 |

53 |

0,2 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A7 |

| J15ER/L V2-1 |

15 |

53 |

0,1 |

0 |

2 |

a |

k |

b |

b |

- |

- |

A6 |

| J15ER/L V2-0-2 |

15 |

53 |

0 |

0,2 |

2 |

b |

k |

b |

b |

- |

- |

A6 |

| J15ER/L V12-2 |

15 |

53 |

0,2 |

0 |

12 |

b |

k |

b |

b |

r |

r |

A7 |

| J15ER V12-4 |

15 |

53 |

0,4 |

0 |

12 |

r |

k |

r |

r |

r |

r |

A7 |

| J15ER V12-4-28 |

15 |

62 |

0,4 |

0 |

12 |

r |

k |

r |

r |

- |

- |

A7 |

| J20ER V12-4 |

20 |

53 |

0,4 |

0 |

12 |

- |

- |

- |

- |

r |

r |

A7 |

|

|

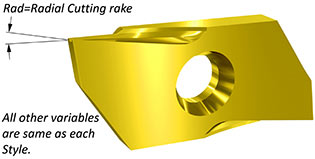

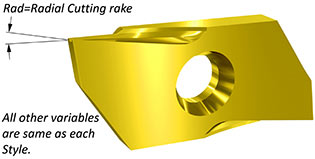

Style HP, JP, VP| Inserts for Turning in Sticky Materials

| |

|

|

|

|

|

|

|

STOCK |

PRICE

GROUP |

| INSERTS |

L |

V° |

R1 |

R2 |

C |

Ax |

Rad |

8M |

F8 |

B8 |

NF8 |

ND8 |

| J11ER HP6-0 |

11 |

3 |

0 |

- |

0 |

6 |

6 |

r |

r |

r |

r |

r |

A5 |

| J11ER HP6-05 |

11 |

3 |

0,05 |

- |

0 |

6 |

6 |

r |

r |

r |

r |

r |

A6 |

| J15ER HP8-1 |

15 |

3 |

0,1 |

- |

0 |

8 |

12 |

- |

- |

- |

r |

r |

A5 |

| J15ER HP8-2 |

15 |

3 |

0,2 |

- |

0 |

8 |

12 |

- |

- |

- |

r |

r |

A5 |

| J15ER HP16-0 |

15 |

3 |

0 |

- |

0 |

16 |

12 |

r |

r |

r |

- |

- |

A4 |

| J15ER HP16-03 |

15 |

3 |

0,03 |

- |

0 |

16 |

12 |

r |

r |

r |

- |

- |

A5 |

| J15ER HP16-05 |

15 |

3 |

0,05 |

- |

0 |

16 |

12 |

r |

r |

r |

- |

- |

A5 |

| J15ER HP16-2 |

15 |

3 |

0,2 |

- |

0 |

16 |

12 |

r |

r |

r |

r |

r |

A5 |

| J15ER JP12-0 |

15 |

12 |

0 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A4 |

| J15ER JP20-1 |

15 |

12 |

0,1 |

- |

0 |

20 |

12 |

r |

r |

r |

- |

- |

A5 |

| J20ER JP20-4 |

20 |

12 |

0,4 |

- |

0 |

20 |

12 |

r |

r |

r |

r |

r |

A24 |

| J15ER DP8-4 |

15 |

33 |

0,4 |

- |

0 |

8 |

12 |

- |

- |

- |

r |

r |

A6 |

| J15ER DP12-0 |

15 |

33 |

0,02 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A6 |

| J15ER DP12-05 |

15 |

33 |

0,05 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A7 |

| J15ER DP12-1 |

15 |

33 |

0,1 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A6 |

| J15ER DP12-15 |

15 |

33 |

0,15 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A6 |

| J15ER DP12-2 |

15 |

33 |

0,2 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A6 |

| J15ER NP12-0-2 |

15 |

48 |

0 |

- |

0,2 |

12 |

12 |

r |

r |

r |

- |

- |

A7 |

| J15ER NP12-03-1 |

15 |

48 |

0,03 |

- |

0,15 |

12 |

12 |

r |

r |

r |

- |

- |

A8 |

| J15ER NP12-05-1 |

15 |

48 |

0,05 |

- |

0,15 |

12 |

12 |

r |

r |

r |

- |

- |

A8 |

| J15ER NP12-052 |

15 |

48 |

0,05 |

0,2 |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A8 |

| J15ER NP12-08 |

15 |

48 |

0,08 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A8 |

| J15ER NP12-2 |

15 |

48 |

0,2 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A8 |

| J15ER NP12-1-3 |

15 |

48 |

0,1 |

- |

0,3 |

12 |

12 |

r |

r |

r |

- |

- |

A8 |

| J15ER VP12-05 |

15 |

53 |

0,05 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A8 |

| J15ER VP12-08 |

15 |

53 |

0,08 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A8 |

| J15ER VP12-2 |

15 |

53 |

0,2 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A8 |

| J15ER VP12-4 |

15 |

53 |

0,4 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A8 |

| J15ER MP12-2 |

15 |

72,5 |

0,2 |

- |

0 |

12 |

12 |

r |

r |

r |

- |

- |

A8 |

| J15ER MP12-4 |

15 |

72,5 |

0,4 |

- |

0 |

12 |

12 |

r |

r |

r |

r |

r |

A8 |

|

Benefits of P-line

- The P-line inserts have the same basic geometry as the equivalent Style: H=HP, J=JP, D=DP, N=NP, V=VP, M=MP.

- The difference is the radial cutting rake, which varies from 6-12°.

- The P-line insert offer greater chip control/breaking in materials that easy gives a built up edge.

- Reduced risk of a built up edge.

- Less cutting pressure = better surface finish.

- Outstanding performance in titanium, stainless and carbon steels.

- Improved surface finish when copy turning in all materials.

|

|

Style M | Inserts

for Profile and Copy Turning

| |

|

|

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

L |

t |

V1° |

V2° |

R |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| J15ER M12-08 |

15 |

1,3 |

17,5 |

17,5 |

0,08 |

12 |

r |

k |

r |

k |

- |

- |

A7 |

| J15ER M12-2 |

15 |

1,3 |

17,5 |

17,5 |

0,2 |

12 |

r |

k |

r |

k |

r |

r |

A7 |

|

|

Style F | Inserts for Reverse Turning and Finishing

| |

|

|

|

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

R1 |

R2 |

C |

t |

F |

V° |

8M |

C8 |

F8 |

B8 |

| J15ER FD16-0320 |

0,03 |

0,2 |

0 |

0,6 |

3 |

33 |

16 |

r |

k |

r |

k |

A8 |

| J15ER FD16-0520 |

0,05 |

0,2 |

0 |

0,6 |

3 |

33 |

16 |

r |

k |

r |

k |

A8 |

| J15ER FN8-0520C |

0,05 |

0,2 |

0,05 |

0 |

- |

48 |

8 |

k |

- |

k |

k |

A8 |

| J15ER FN8-1020C |

0,1 |

0,2 |

0,03 |

0 |

- |

48 |

8 |

k |

- |

k |

k |

A8 |

| J15ER FN20-1818C |

0,18 |

0,18 |

0,03 |

0 |

- |

48 |

20 |

r |

- |

r |

r |

A8 |

Benefits of reverse turning

- Higher feed with an improved surface finish.

- Clears burrs on sharp corners.

- Corner radius protected when turning.

- Increased tool life.

- Angled cutting edge gives smoother cutting.

|

|

| Inserts to be used with J-type Tool holder |

L

11

15

20 |

T

2,5

2,1

3,5 |

|

Stock status

a = Stock standard in ER and EL

b = Stock standard in ER; EL against inquiry

c = Stock standard in EL; ER against inquiry

r = Stock standard in ER only

l = Stock standard in EL only

k = ER and EL against Inquiry |

|